We provide non-destructive single and serial testing of your components. Our company is certified to ISO 9001 for industry and EN 9100 for aviation. Our test center has GE, MTU and Rolls-Royce approval in accordance with RRP58001 for ultrasonic testing of turbine disks and 1000Gates.

Whether for single parts or large series, we offer customized testing concepts for a wide range of requirements. We also support our customers in the early development phase: through feasibility studies and inspection planning, we ensure that your components can be tested efficiently and reliably later on.

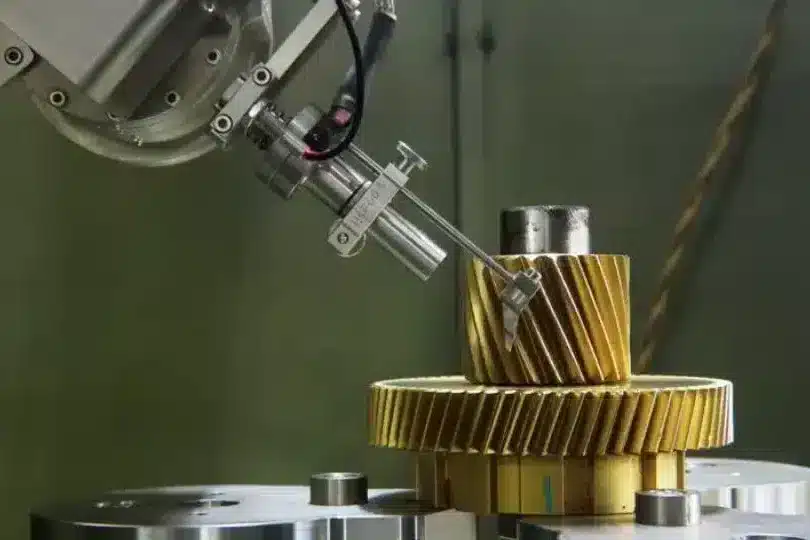

Ideal for detecting and defining internal defects in homogeneous materials.

Suitable for detecting surface and near-surface cracks in ferromagnetic materials.

Suitable for detecting surface and near-surface cracks in ferromagnetic materials.

Used to detect surface defects and visible irregularities.

Thanks to our comprehensive portfolio of non-destructive testing services, we are able to use the most suitable testing method and solution for your testing tasks. We take on the non-destructive individual and series testing of your components as a service in our test center.

For over 40 years, we have been working with our customers to set the course for fewer rejects, fault-free components and risk-free product use.